Thread looping on the bottom of your fabric:

Thread looping on the bottom of your fabric is usually caused by little or no top tension or too much bobbin tension. Another cause is thread or lint caught in the top tension

– Make sure the thread is between the tension discs and that no thread or lint is caught.

– Check that your top tension is set to a medium number.

– The thread should pull from the bobbin tension evenly. You should not have to pull too hard.

– Make sure the thread is in the take-up lever.

Top thread breaking:

There are a few reasons the top thread may break.

– Check the needle plate for damage around the needle hole. You can polish any burrs with fine sand paper or a needle file.

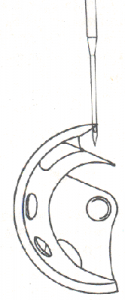

– Check the hook for damage. If the hook is damaged it can cause the thread to break as it comes off the tip. Be very careful if you must remove burrs from the hook. Changing the shape of the hook tip will cause skipping problems.

– Check that the top tension is not too high. The top tension should be set at a medium number for regular sewing.

Needle breaking:

– Check that the top tension is not too tight. The top tension should be set at a medium number for regular sewing.

– Check needle size for the thickness of your fabric. Using a needle that is too small for the type and thickness of fabric you are using will cause the needle to bend and hit the hook.

– The hook timing may be out. Insert a new needle and carefully turn the hand wheel towards you. Check that the needle is not going to hit the hook.

Bobbin thread will not pick up:

The main reason could be the way the needle is inserted.

– Check if the needle is inserted correctly for your machine. The flat of the needle must be inserted toward the hook tip. The thread sits in the grove in the front of the needle and is picked up by the hook in the scarf on the back of the needle. Also check that the needle is not blunt or bent as this will cause the hook to miss the thread.

– Make sure the take-up lever is threaded

– The hook timing may be out. The hook tip and needle scarf must meet at the right point for the thread to be picked up and create the stitch.

Fabric will not feed:

– Check that the feed dogs are up. Some machines have a feed drop feature for darning. Make sure the machine is set for sewing and not darning. Also check that lint is not clogging up the grooves in the feed dogs. Lint can build up over time and push the feed dogs down below the needle plate.

– Check the pressure on the pressure bar. You require pressure on the foot to feed the fabric. No pressure and the fabric will just sit in one spot.

– Check that the pressure foot is installed properly. If the foot is not installed right the fabric may not feed.

– Check for ruff spots on the needle plate as fabric can get caught.